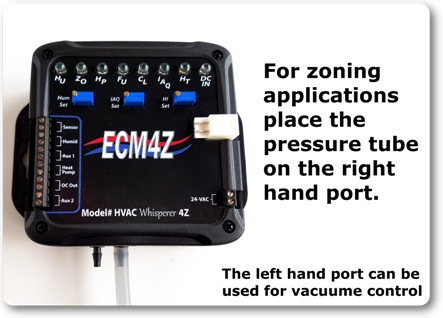

Zoned Systems (Eliminate the bypass damper!)

ECM MODULATOR 4Z for Zoned systems

ELIMINATES THE NEED FOR BYPASS DAMPERS

The ECM Modulator 4Z measures and maintains the duct static pressure in a zoned system. As some zones close down and the system pressure starts to build, the ECM Modulator 4Z imediately senses this and reduces the blower’s speed so that the systems pressure stays at your set point. Thus the proper air movement from the open zones is maintained. During the times when there is no call for heat or cooling, and constant fan is desired, the ECM Modulator can be set to drop to any slow speed that you choose. In this way, all IAQ products will remain operating and at the highest possible efficiency.

INSTALLATION AND SETUP

Installation and wiring must comply with all local and national electrical codes.

Only qualified HVAC/IAQ technicians and service mechanics may install the ECM modulator control. To do otherwise will void all warranties.

CRUISE CONTROL FOR ZONED SYSTEMS

ELIMINATING BYPASS DUCTS AND DUMP ZONES

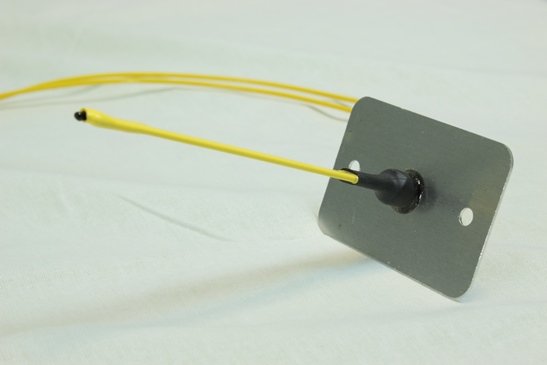

Temperature sensor

Place this

Place this

in the

delivered air

Pressure pick up plate and tubing.

Place this

Before any

Zone dampers

or registers.

Connect pressure tube to control

After the Installation is complete. It is now time to set the desired duct pressure. Usually the smallest zone is of the greatest concern. The ECM Modulator 4Z is calibrated at the factory to hold about .3 inches of water column. Try closing all the dampers except for the one(s) controlling the smallest zone, if it is noisy and you want to reduce the pressure. Keep in mind that the duct pressure that you set for the smallest zone is the same pressure that the ECM Modulator 4Z will try to maintain when all dampers are open.

Setting Your Maximum Duct Pressure

On the ecMModulator 4Z controls the HI SET pot is used to adjust the pressure limit. Turning the pot clockwise will increase the maximum duct pressure and counter clockwise will decrease the maximum duct pressure. 2 full turns will approximately equal 0.1" wc. ecMModulator 4 Z controls are shipped with a factory duct pressure setting of about 0.3” wc. Before you begin setting the pressure re-move the temperature sensor wire from the control (top terminal). This will drive the blower up to and slightly past the present pressure setting speed. Wait while the blower’s speed settles before changing the pressure setting. If you want to control from pressure alone, then just remove the temperature sensor and leave it off. A step by step procedure for adjusting the pressure is listed below.

- Re-move the temperature sensor wire from the control to cause the motor to go full speed.

- For a higher pressure, turn the screw on the HI SET pot clockwise.

- For a lower pressure, turn the screw on the HI SET pot counterclockwise.

- If the pressure is close to what you want, turn the pot slowly about a quarter turn at a time to give the motor and control time to adjust. A rough calculation is that about two turns will change the pressure about 0.1” wc.

- When you are at or above the programmed pressure setting, the ZO light will be on.

- If you overshoot the adjustment and wish to reverse the setting you made, you can figure that it takes about 1/4 turn to take up the slack in the pot’s clutch before you will notice a change.

Once you achieve the pressure setting you want, reconnect the sensor wire.

NOTE: The ECM Modulator is not a safety or limit control. It does not eliminate the need for a low temperature or pressure cut out and a high temperature limit control. To leave these out of any zoned system is poor design and improper practice.